Manholes

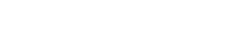

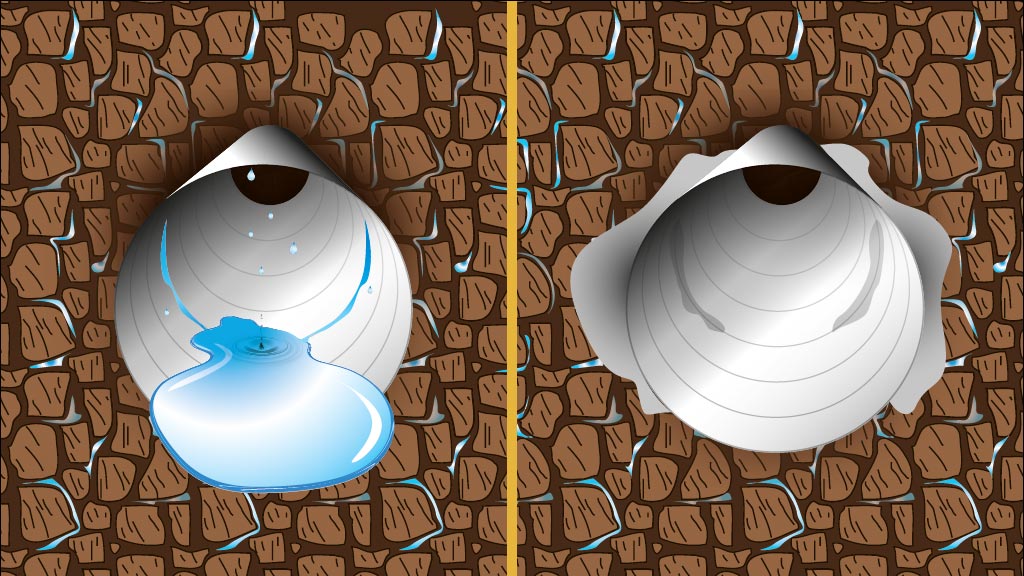

Stopping fluid infiltration into a structure or manhole is difficult due to the increase in fluid pressure as the repair process continues. GeoGrout addresses the problem by cutting off the fluid flow from the outside of the structure. Typically the repair process is carried out by advancing a series of injection probes around the structure from the ground surface to the zone in question. The injection process creates a permanent grout plug on the outside of the structure. Since the grout plug is always in compression, an increase in fluid pressure does not affect the repair.

Alternatively, the pressure grouting may be carried out through injection probes advanced through the structure walls. These probes are left in place until the grout sets, then removed and the holes repaired.

GeoGrout has incorporated site specific grout mixes to stop fluid flows upwards from 45 litres/minute (10 gallons/minute) or more, utilizing these techniques.